Construction decription of PNCT Rubber Cable

Voltage: 600/1000V, 3000V Or other

Color: Black or by request.

Conductor: Flexible Copper/Tinned Copper

Insulation: Rubber/EPR

Cores: 1,2, 3, 4, 5, 6, 7, 8 Core and more cores

Application: the the application ranges high tension unloader, impact resistance, Stacker & Reclaimer Abrasion Resistance Gantry, Craneetc.

Standard: JIS C3327/IEC/VDE etc

Packaging: Iron or Wooden Drum

Learn More Flexible Rubber Cable

- Flexible PVC/Rubber Sheath Welding Cable

- Waterproof Subermersbile Pump Cable

- Resistance Oil and Water SJOOW/SOOW/SJO Cable

- H07RN-F Heave Duty Mobile Equipmen Rubber Cable

- SJOOW/SOOW/SJO Cable

- Trailing Cable with Optica Fiber Composite Cable

- Reeling/Festoon Crane Cable

- Welding Cable

- Pendant Hoist Cable

- Spreader Hoist Cable

- PNCT Rubber Cable Used for Machine Equipment

- Rubber Cable Products List

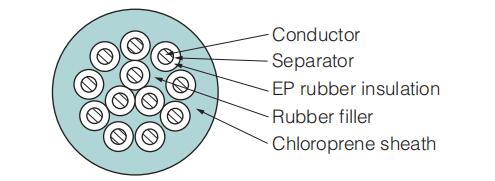

The Feature of CUR-2PNCT (Festoon System)

– High flexibility and bending resistance.

(however, not suitable for applications where

cables are subjected to lateral pressure, such

as carrier drum system)

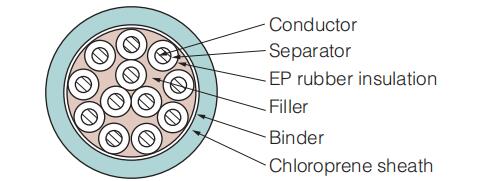

The Feature of CAR-2PNCT (Carrier DrumSystem)

High resistance to lateral pressure.

– Reduced cable corkscrewing by making rubber

sheath solidal structure.

– Robust type of chloroprene is used as sheath.

The Feature of RE-2PNCT (Carrier Drum System)

– High resistance to lateral pressure.

– Reduced cable corkscrewing by making rubber

sheath solidal structure.

– Robust type of chloroprene is used as sheath.

The Feature of H-2PNCT (Reel System)

– High resistance to lateral pressure and wear.

– Robust type of chloroprene is used as sheath.

– Weather Resistance, Flame Retardance,Bending Resistance

– Suitable for Unloader, Stacker & Reclaimer, Crane, etc

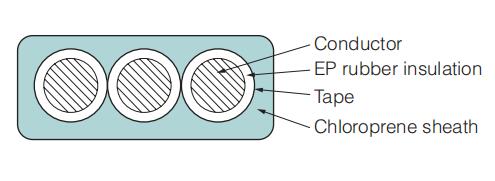

The Feature of SK-2PNCT (Festoon System)

– High flexibility and bending resistance.

(however, not suitable for reeling system)

– More efficient cable installation because of its

smaller bending radius than those of round cable.

The Feature of TOR-2PNCT (Torsion System)

– High torsion resistance.

– Improved slipping performance between cores by

individually taping on each core.

0.6/1KV HT-PNCT-F Rubber Cable Parameter Sheet

| Number | Conductor Composition | Outer Diameter | Thickness of Insulation | Thickness of Sheath |

Insulation Resistance (20 )(Min.) | Weight |

| Corexsqmm | Max./mm | mm | mm | mm | km | kg/km |

| 3×16 | 0.26 | 6 | 1.2 | 2.3 | 300 | 930 |

| 3×25 | 0.26 | 7.4 | 1.2 | 2.5 | 300 | 1290 |

| 3×35 | 0.26 | 8.7 | 1.2 | 2.7 | 200 | 1650 |

| 3×50 | 0.26 | 10.4 | 1.5 | 3 | 200 | 2290 |

| 3×95 | 0.26 | 14.5 | 2 | 3.7 | 200 | 4170 |

| 3×120 | 0.26 | 16.2 | 2 | 4 | 200 | 5090 |

| 3×150 | 0.26 | 18.2 | 2 | 4.2 | 200 | 6150 |

| 3×185 | 0.26 | 20.2 | 2.5 | 4.6 | 200 | 7710 |

| 4×25 | 0.31 | 7.4 | 1.2 | 2.7 | 300 | 1790 |

| 4×35 | 0.31 | 8.7 | 1.2 | 2.9 | 200 | 2290 |

| 4×50 | 0.31 | 10.4 | 1.5 | 3.2 | 200 | 3160 |

| 4×95 | 0.31 | 14.5 | 2 | 4 | 200 | 5720 |

| 4×120 | 0.31 | 16.2 | 2 | 4.3 | 200 | 6980 |

| 4×150 | 0.31 | 18.2 | 2 | 4.6 | 200 | 8450 |

| 4×185 | 0.31 | 20.2 | 2.5 | 5.1 | 200 | 10690 |