VFD cable organizes and protects variable frequency drive input and motor power wiring, and is designed to reduce VFD-related interference (EMI) on nearby equipment.

These shielded multi-conductor cables have a black thermoplastic elastomer (TPE) outer jacket, and are available with 4 conductors in up to 2 AWG wire size.

A variety of constructions and voltages are available including 600V, 2KV, 2KV armored & sheathed, and 8KV and 15KV medium voltage armored & sheathed. Grounding systems are offered in full conductor size, 3 symmetrical bare, and 3 symmetrical insulated. Shielding options include copper tape shield, tinned copper braid + poly aluminum tape, and tinned copper armor + aluminum poly tape. Whether onshore or offshore, in a refinery or on a platform, HWC has the right VFD power cable for your application.

Another Cable type for mobile equipment

H07RN-F Cable 2PNCT Cable SJOOW/SOOW/SJO Cable Submersible Pump Cable Trailing Cable with Optical Fiber Composite Reeling/Festoon Crane Cable Welding Cable Pendant Hoist Cable Elevator Traveling Cable Spreader Basket Cable VFD Cable4 core EMC VFD Cable (0.6/1kv XLPE /LSZH)

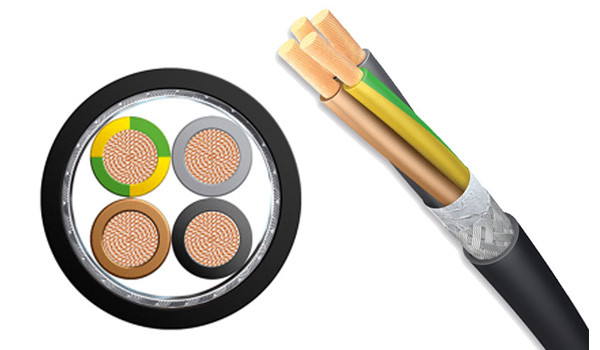

Operating Voltage: 0.6/1 kV

Conductor: Stranded Annealed Copper (IEC/EN 60228, Class 5)

Insulation: XLPE (Cross-Linked Polyethylene) Identification – HD 308 S2

Lay-up: 4 cores twisted together

Separator: Al-PET Foil

Screen: Tinned Copper Wire Braid

Outer Jacket: Halogen Free Flame Retardant Compound (LSZH) RAL 9005 – Black

Temperature Range Operating: -30°C…+90°C

Application: Used in frequency converter-controlled motors for control and/or power purposes, and suitable for use in dry, moist or wet environments in heavy industries. HFFR types are less flammable in case of fire, mostly self-extinguishing, have low smoke density and they do not emit poisonous and corrosive gasses during a fire.

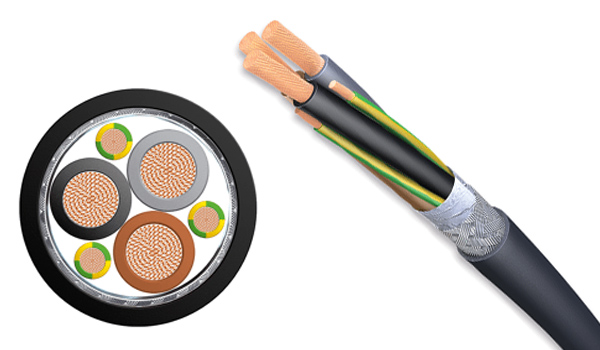

3+3Core EMC VFD Cable for Variable Frequency Drives

Operating Voltage: 0.6/1 kV

Conductor: Electrolytic copper, class 5 (flexible),

Grounding Conductor: The grounding conductor is divided into three conductors; the equivalent cross section is approximately 50% of the section of the phase conductor.

Insulation: Cross-linked polyethylene (XLPE)

4G : gray + brown + black + Yellow/Green (up to 10 mm2)

3x + 3G : gray + brown + black + Yellow/Green (3G) (from 16 mm2)

Screen: Aluminium-polyester tape screen, helically placed over the insulated conductors. Over the tape there is a tinned copper braid screen. The tape and the braid act as a double screen to cut out all of the electromagnetic interference.

Outer Jacket: Polyolefin LSZH outer sheath with ripcord to allows for ease of stripping of the outer jacket

0.6/1KV 3+3 Core XLPO VFD Power Cable

Voltage: 600/1000V Type TC-ER, -25°C to 90°C

Conductor: Stranded tinned copper circuit conductors

Insulation: XLPO(Crossed-linked polyolefin, flexible and low dielectric)

Color Code: 262MCM and larger: black and numbered

4/0AWG and smaller: red, white, black

Grounding Cable: 3 Symmetrical Bare Grounds

Shield Layer: Copper Tape Shield

Jacket: Black sunlight resistant polyvinyl chloride (PVC)

Advantage Feature:

Type TC-ER 600V

- 1kV Flexible Motor Supply Cable (up to 4/0 AWG)

- 90°C Temperature Rating

- Sunlight Resistant

- Oil Resistant (Oil Res I)

3+3 Core XLPE VDF Cable technical parameter

| n˚ x Section (mm2) | Diameter under the braid (mm) | Overall Diameter (mm) | Weight (kg/km) |

| 4 G 1,5 | 7,0 | 10,4 | 155 |

| 4 G 2,5 | 7,9 | 11,3 | 195 |

| 4 G 4 | 9,2 | 12,4 | 260 |

| 4 G 6 | 10,6 | 14,0 | 345 |

| 4 G 10 | 12,9 | 17,2 | 595 |

| 3 x 16 + 3 G 2,5 | 13,5 | 17,2 | 670 |

| 3 x 25 + 3 G 4 | 16,8 | 21,4 | 1085 |

| 3 x 35 + 3 G 6 | 19,4 | 24,1 | 1455 |

| 3 x 50 + 3 G 10 | 22,8 | 28,0 | 2025 |

| 3 x 70 + 3 G 10 | 27,1 | 32,5 | 2650 |

| 3 x 95 + 3 G 16 | 30,5 | 36,1 | 3455 |

| 3 x 120 + 3 G 16 | 34,6 | 41,0 | 4345 |

| 3 x 150 + 3 G 25 | 38,9 | 45,5 | 5450 |

| 3 x 185 + 3 G 35 | 43,4 | 50,4 | 6755 |

| 3 x 240 + 3 G 50 | 49,2 | 56,6 | 8680 |

| 3 x 300 + 3 G 50 | 55,3 | 63,0 | 10695 |

3+3 Core XLPO VDF Cable technical parameter

| Size (AWG/ kcmil) |

Number of Conductor | Conductor Stranding | Insulation Thickness (inches) | Ground Wire Size (AWG) | Ground Wire Stranding | Jacket Thickness (inches) | Overall Dia. (inches) | Weight (lbs/Mft.) |

| 14 | 3 | 19 | 0.030 | 18 x 3 | 19 | 0.06 | 0.466 | 158 |

| 12 | 3 | 19 | 0.030 | 16 x 3 | 19 | 0.06 | 0.509 | 199 |

| 10 | 3 | 37 | 0.030 | 14 x 3 | 19 | 0.06 | 0.552 | 258 |

| 8 | 3 | 37 | 0.045 | 14 x 3 | 19 | 0.06 | 0.653 | 368 |

| 6 | 3 | 61 | 0.045 | 12 x 3 | 19 | 0.06 | 0.737 | 517 |

| 4 | 3 | 133 | 0.045 | 12 x 3 | 19 | 0.08 | 0.956 | 814 |

| 2 | 3 | 133 | 0.045 | 10 x 3 | 37 | 0.08 | 1.103 | 1,178 |

| 1 | 3 | 209 | 0.055 | 10 x 3 | 37 | 0.08 | 1.221 | 1,462 |

| 1/0 | 3 | 266 | 0.080 | 10 x 3 | 37 | 0.08 | 1.447 | 1,886 |

| 2/0 | 3 | 323 | 0.080 | 10 x 3 | 37 | 0.08 | 1.538 | 1,951 |

| 4/0 | 3 | 532 | 0.080 | 8 x 3 | 37 | 0.11 | 1.883 | 3,102 |

| 262 | 3 | 646 | 0.065 | 6 x 3 | 61 | 0.11 | 1.981 | 3,642 |

| 313 | 3 | 777 | 0.065 | 6 x 3 | 61 | 0.11 | 2.08 | 4,658 |

| 373 | 3 | 925 | 0.065 | 6 x 3 | 61 | 0.11 | 2.215 | 5,318 |

| 444 | 3 | 1110 | 0.065 | 6 x 3 | 61 | 0.11 | 2.367 | 6,177 |

| 535 | 3 | 1332 | 0.080 | 6 x 3 | 61 | 0.11 | 2.676 | 7,787 |

| 646 | 3 | 1591 | 0.080 | 4 x 3 | 133 | 0.14 | 2.893 | 9,155 |

| 777 | 3 | 1924 | 0.080 | 4 x 3 | 133 | 0.14 | 3.164 | 10,914 |