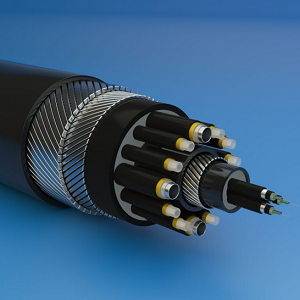

Umbilical cable is an important facility in the subsea production system for the offshore oil exploitation. It provides a control and communication link between the surface vessel and the subsea equipment. The umbilical cable is a composite structure that is composed of multiple components and various materials. A typical umbilical cable usually consists of tubes or hoses, optical fibre cables, electrical cables, inner sheaths and fillers which are assembled into an inner core. Steel armor wires are used to provide the tension capability or to achieve the necessary stability. The outer sheath provides protection for the inner components (ISO, 2009). Umbilical cables should maintain sufficient tension stiffness to withstand large loads induced by self-weight, wave and the motion of the surface vessel, which leads to an urgent requirement for the prediction of the mechanical behaviour.

Umbilical cable for ROV

Fiber Count : 1~20cores

Electric Unit : 4 x 3 x 4m2 (category 5)

Inner sheath : Black HDPE

Outer armoure : Galvanised steel wire(GSW)

Outer sheath : Black HDPE

Applications: used for early warning and monitoring

of coastal waters and ports.

Features: longitudinal water-ingress proof cable core section

good flexibility, excellent repeated bending performance, retractable in numerous times

transmission of both optical signals and power feeding

Double HDPE layers, excellent redial water blocking performance

12 Cores Umbilical Cable

Strength member: Vectran fiber braid

Outer jacket: Orange polyurethane (1,5 mm)

Outside diameter: Ø 12,2 mm

Electrical resistance conductors 18 AWG : < 19,50 ohm/km @ 20°C

Working voltage :250 V

Weight in air :155 kg/km

Weight in fresh water: 38 kg/km

Weight in sea water :35 kg/km

Breaking strength :1500 kg

Working load max.: 375 kg

Static bending radius min. :61 mm

Dynamic bending radius min. :122 mm

Operating temp -40°c – +90 °C

Length available up to 1000 m